About us

The GOLDINA company dates back to the Karl Loy Bandweberei GmbH company. This company was founded in Munich in 1914 and since then has been producing ribbons for student associations. Medal ribbons, cords, decoration ribbons, rosettes and other products for tournament and club requirements were added later. The GOLDINA company was founded as an independent company in 1970 in order to expand the activities of the Karl Loy company in the decoration ribbon sector. GOLDINA took over the artfleur company in 2010 and since then markets its ribbons in the floristry sector under the artfleur Da Vinci brand.

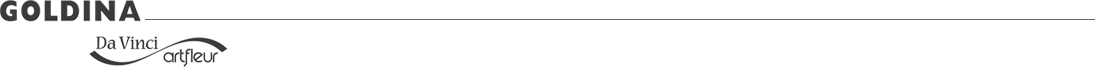

Today the business can access three production locations in Landsberg am Lech, Velbert-Langenberg and a works in Beroun/ Czech Republic and belongs to the leading suppliers in Europe.

Both companies are managed today in the fourth generation by

Mr. Bernhard Hackenberg and Mr. Till Hackenberg.

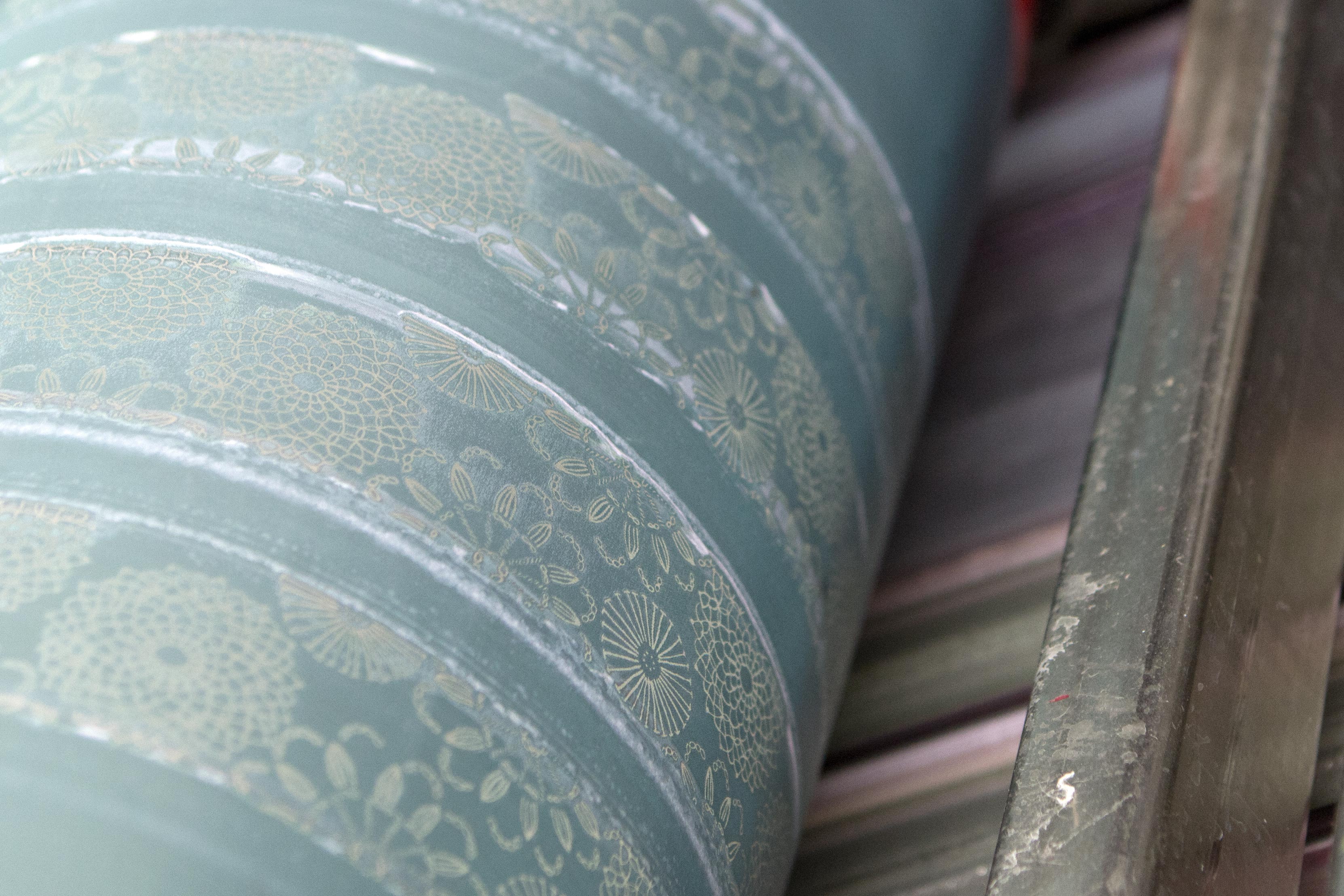

Each year the GOLDINA team together with experienced designers creates a completely new Spring and Christmas collection. Collages of trend themes are created and to each of these matching new decoration ribbons are developed.

Each year the GOLDINA team together with experienced designers creates a completely new Spring and Christmas collection. Collages of trend themes are created and to each of these matching new decoration ribbons are developed. The GOLDINA company strives to build up long-term and partnership-based relationships with its customers and to intensify them through consultation and the development of concepts together. Our sales teams in Landsberg and Velbert are at your disposal for this.

The GOLDINA company strives to build up long-term and partnership-based relationships with its customers and to intensify them through consultation and the development of concepts together. Our sales teams in Landsberg and Velbert are at your disposal for this.

Our distributing warehouses ensure trouble-free distribution and modern logisitics:

Our distributing warehouses ensure trouble-free distribution and modern logisitics: